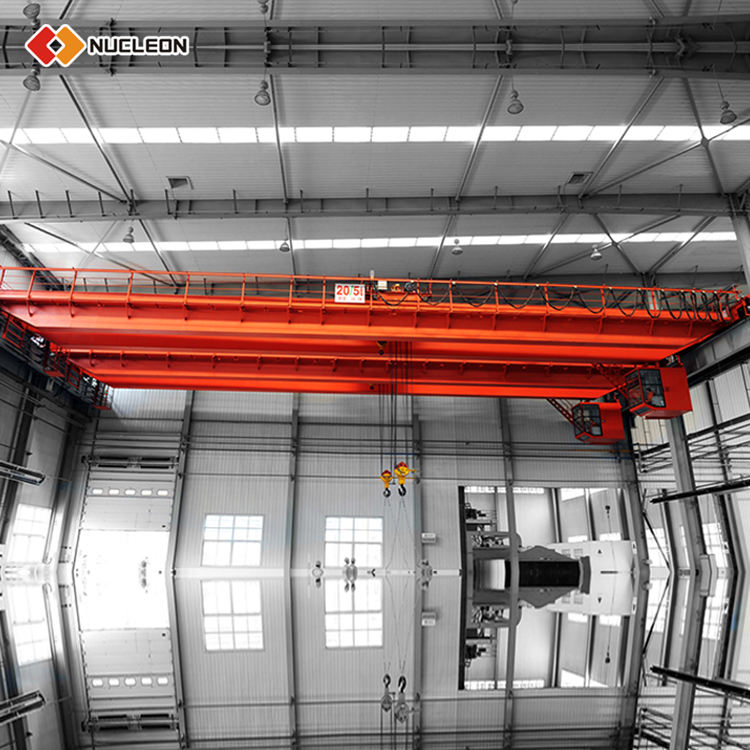

Introduction: Where Safety Meets Heavy Lifting

In industrial settings where flammable gases, vapors, or combustible dusts are present, standard lifting equipment isn't just inadequate—it's a potential ignition source for catastrophic events. The explosion-proof hoist double girder overhead crane represents the pinnacle of safe material handling technology for these high-risk environments. Engineered to prevent ignition in classified hazardous areas, this specialized crane combines the robust lifting capacity of a double girder design with intrinsically safe operation, protecting both personnel and facilities.

This comprehensive guide explores the technical specifications, applications, and critical benefits of this essential equipment for industries operating under constant threat of explosion.

What Makes a Crane Explosion-Proof?

An explosion-proof hoist double girder overhead crane is not merely "spark-resistant." It is a fully engineered system where every component is designed to:

Contain any internal explosion within the device housing

Prevent ignition of the surrounding hazardous atmosphere

Operate at safe surface temperatures below the auto-ignition point of specific gases or dusts

Key Standards and Certifications

ATEX Directive (EU): Equipment for use in potentially explosive atmospheres

IECEx System (International): International certification for explosive atmospheres

NEC/CEC (North America): Class/Division system with Groups for gas/vapor (A-D) and dust (E-G)

ISO 80079 Series: International standards for explosive atmospheres

Technical Design & Critical Components

Double Girder Structural Advantage

The double girder configuration provides superior benefits for explosion-proof applications:

Enhanced Stability: Two bridge girders offer greater hook height and load stability, crucial for precise, safe handling in hazardous zones

Dedicated Trolley Pathway: The trolley runs between the girders, allowing optimal placement of explosion-protected components

Higher Capacity Range: Typically handles capacities from 5 to 550 tons, suitable for heavy, critical processes in petrochemical or pharmaceutical plants

Explosion-Proof Hoist Mechanism

The hoist is the heart of the system, featuring multiple layers of protection:

Motor Enclosure: Cast iron or hardened aluminum housing that withstands and contains internal pressure from an explosion

Temperature Management: Class T1-T6 ratings ensure surface temperatures remain below the ignition point of specified hazardous materials

Braking System: Fail-safe, spring-set brakes with spark-free operation during engagement

Electrical Components: All connections, limit switches, and control pendants are sealed or purged to prevent spark generation

Electrical System & Control Protection

Pressurized Enclosures (Purged Systems): Uses clean air or inert gas to maintain positive pressure, preventing hazardous atmosphere entry

Intrinsically Safe Circuits: Limits electrical energy to levels incapable of causing ignition

Explosion-Proof Conduit and Wiring: Sealed conduits and specially designed cable glands maintain integrity

Primary Applications in Hazardous Industries

Oil, Gas & Petrochemical Plants

Handling drilling equipment, pipe sections, and process vessels in areas with potential hydrocarbon releases. Zones classified as Class I, Division 1 or Zone 1.

Pharmaceutical & Chemical Manufacturing

Processing volatile solvents and powdered compounds where combustible dust (Class II/III) or flammable vapors (Class I) are present during mixing, transfer, or packaging.

Grain Handling & Food Processing

Elevators, silos, and processing areas where combustible dust from grains, sugars, or starches can form explosive atmospheres (Class II, Group G).

Aerospace & Military

Painting booths with flammable coatings (Class I, Division 1), and facilities handling explosive materials or propellants.

Advantages Over Standard Overhead Cranes in Hazardous Areas

Unmatched Safety Compliance

Eliminates Ignition Sources: Designed so sparks, arcs, or hot surfaces cannot trigger an explosion

Regulatory Assurance: Meets stringent OSHA, NFPA, and international standards for hazardous location operation

Comprehensive Documentation: Provides certified drawings, manuals, and inspection records for compliance audits

Operational Reliability & Uptime

Rugged Construction: Components withstand corrosive and abrasive environments common in chemical or mining applications

Reduced Facility Downtime: Enables continuous operations in classified areas without requiring hot work permits for standard equipment

Predictable Maintenance: Designed for easy inspection and maintenance without compromising explosion-proof integrity

Total Cost of Ownership Benefits

Insurance Premium Reduction: Many insurers offer lower rates for facilities using certified explosion-proof equipment

Accident & Liability Prevention: Mitigates risk of catastrophic loss from explosions, protecting assets and human capital

Long Service Life: High-grade materials and protection extend equipment lifespan despite harsh environments

Selection Guide: Choosing the Right Specification

Step 1: Hazardous Area Classification

Identify the specific Class, Division/Zone, and Group for your application location. This determines the required protection level.

Step 2: Capacity & Span Requirements

Lifting Capacity: Include future process needs; consider 25-30% overhead for safety

Bridge Span: Distance between runway rails; affects girder strength and deflection

Lift Height: Consider maximum hook travel needed for your process

Step 3: Duty Cycle & Usage Intensity

FEM or ISO Duty Class: From 1Am (infrequent use) to 5m (continuous severe service)

Hours/Day Operation: Impacts motor sizing and thermal management design

Step 4: Environmental Factors

Ambient Temperature Range: Affects material selection and thermal ratings

Presence of Corrosives: Determines coating and material specifications

Indoor/Outdoor Operation: Requires additional weather protection if outdoors

Maintenance & Inspection: Ensuring Ongoing Safety

Daily/Weekly Checks

Visual inspection of hooks, wire ropes, and load chains

Verification of limit switch operation

Check for unusual noises or vibrations

Monthly/Quarterly Inspections

Detailed examination of electrical connections and seals

Brake adjustment and performance testing

Structural inspection for cracks or deformations

Annual/Certification Inspections

Complete disassembly and inspection by certified technicians

Re-certification of explosion-proof integrity (pressure tests, seal checks)

Electrical insulation resistance testing

The Future of Explosion-Proof Lifting Technology

Increased Integration with IoT

Digital Twins: Virtual models for real-time performance simulation and optimization

Blockchain for Maintenance Records: Immutable logs for compliance and audit trails

Advanced Materials

Composite Enclosures: Lighter, stronger housings with better corrosion resistance

Self-Monitoring Materials: Embedded sensors within components to detect stress or fatigue

Enhanced Protection Methods

Active Explosion Suppression: Systems that detect and suppress incipient explosions within milliseconds

Improved Sealing Technologies: Nanotechnology seals offering longer service life with better integrity

Conclusion: A Non-Negotiable Investment for Safety-Critical Operations

An explosion-proof hoist double girder overhead crane is far more than premium lifting equipment—it is a fundamental engineering control within a facility's overall safety strategy. In environments where flammable substances are processed or present, the choice between standard and explosion-proof equipment is the choice between calculated risk and engineered safety.

The double girder design provides the strength and precision needed for heavy industrial processes, while the explosion-proof certification ensures this power is exercised without introducing catastrophic risk. For engineers, plant managers, and safety officers, specifying this equipment demonstrates a commitment to operational excellence that protects both people and capital investment.

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

https://ncranes.com

Tel

+86-17525962783