In the demanding world of industrial material handling, efficiency, reliability, and safety are non-negotiable. For lifting and moving heavy loads across expansive workspaces, the LH Electric Hoist Double Girder Overhead Crane stands as a premier solution. This article delves into what this crane is, its key features, undeniable advantages, typical applications, and the technical data that proves its superior capability.

What is an LH Electric Hoist Double Girder Overhead Crane?

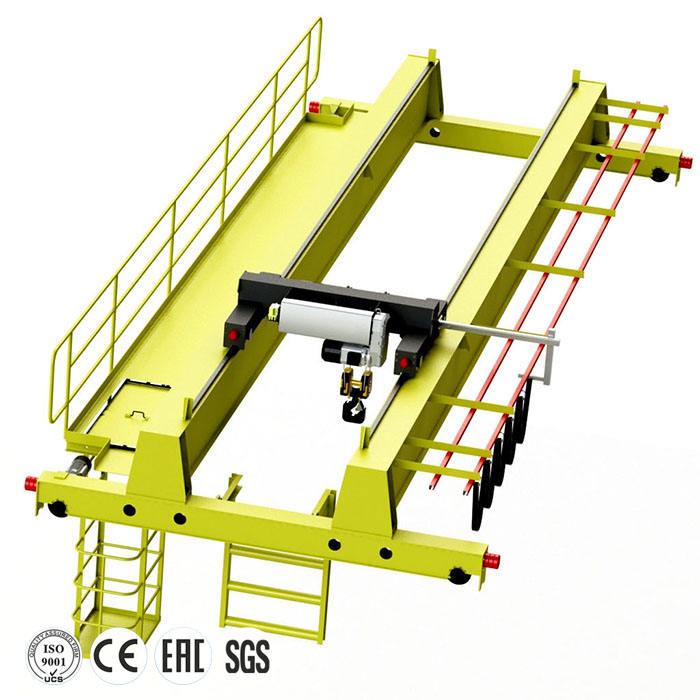

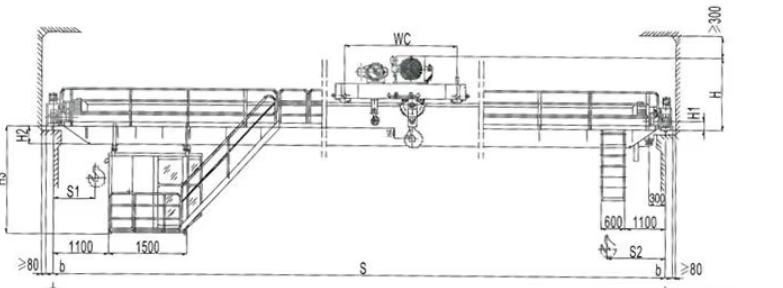

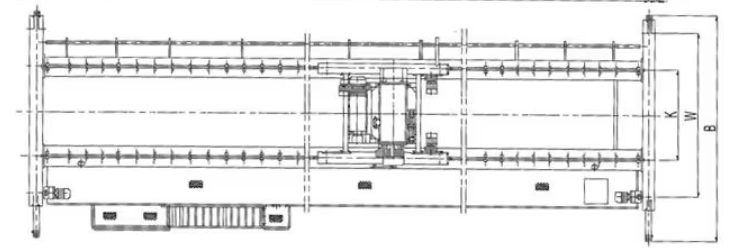

An LH Electric Hoist Double Girder Overhead Craneis a type of heavy-duty, floor-operated or cab-operated crane designed for robust and frequent lifting tasks. The "Double Girder" refers to its primary bridge structure, which consists of two main load-bearing beams that run parallel to each other, supported by end trucks on either side. These end trucks travel on elevated runways fixed to the building's supporting structure. The "LH Electric Hoist" is a modular wire rope hoist unit that is mounted on and travels along the double girders. This configuration creates a highly stable and powerful system capable of handling significant loads over wide spans with exceptional precision.

Product Introduction

The LH series crane integrates a proven electric wire rope hoist with a rugged double girder bridge. Unlike cranes where the hoist is fixed, the LH hoist is a self-contained unit that moves laterally across the girders, offering comprehensive coverage of the work area below. The crane operation can be managed via a pendant push-button station (floor-operated) or from an operator's cab. It is engineered for medium to heavy-duty cycles in factories, workshops, warehouses, and assembly bays, offering a versatile and cost-effective lifting solution for capacities beyond the practical range of single girder cranes.

LH electric hoist overhead crane is mainly used in machining workshop, metallurgical auxiliary workshops, warehouses, material, power etc to transfer, assembly, maintenance and handling operations. It can also replace ordinary double-beam bridge crane. used in light and textile industry and food industry. The work type is light and intermediate. the working environment temperatureis -20-40 ° prohibited working in flammable. explosive. corrosive environment.There are two control models: Ground control and Cabin control; for cabin control, it could be open type and close type. and installed as per actual working need on the left or right side; Driver could enter the cabin by side. rear or top, which depends on different users' requirement.

Key Performance Parameters

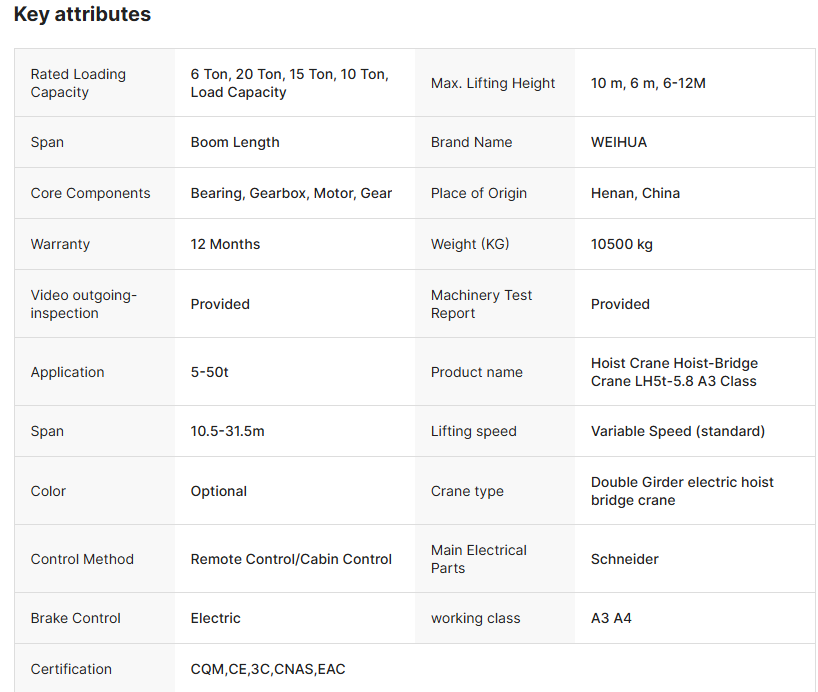

The rated lifting capacity covers multiple grades including 6 tons, 10 tons, 15 tons, and 20 tons, meeting diverse hoisting needs within the 5 to 50-ton range. The maximum lifting height is configurable from 6 meters to 12 meters. The crane span can be customized between 10.5 meters and 31.5 meters to suit various workshop layouts. The total weight of the equipment is approximately 10,500 kg. It is designed for A3 (medium duty) or A4 (heavy duty) work classes, making it suitable for different levels of operational intensity and loading conditions.

Core competition advantage

Core components include bearings, gearboxes, motors, and gears, ensuring transmission reliability and durability. The standard hoisting speed is variable frequency control, enabling smooth and precise load handling. Major electrical components utilize Schneider brand products, and the braking system is electrically controlled, ensuring operational safety.

Superior Strength & Load Capacity: The dual girder design provides immense structural integrity, allowing for higher lifting capacities (typically from 5 tons up to 550 tons or more) and longer spans (up to 35+ meters) compared to single girder cranes. It can accommodate larger hook approaches.

Enhanced Hoist Performance: The dedicated LH electric hoist offers smooth, precise lifting and lowering. Features often include dual-speed control for accurate load positioning, thermal overload protection, and a failsafe electromagnetic disc brake.

Exceptional Durability & Stability: Built with heavy-duty steel sections, the double girder bridge minimizes deflection under load, ensuring stable and sway-free travel of the hoist and load. This leads to safer operation and protects both the crane and the lifted goods.

Optimized Space Utilization: The design allows the hoist to be positioned above the girders (top-running), freeing up the full hook height below the beams. This maximizes usable vertical space in the facility—a critical advantage in buildings with height restrictions.

Low Maintenance & High Reliability: Standardized components, sealed mechanisms, and accessible service points contribute to reduced downtime. The robust construction ensures longevity even in challenging industrial environments.

Robust LH Series Electric Wire Rope Hoist: The heart of the system, known for its durable construction, high duty cycle, and reliable lifting/lowering performance. It delivers consistent power and precise control.

Robust LH Series Electric Wire Rope Hoist: The heart of the system, known for its durable construction, high duty cycle, and reliable lifting/lowering performance. It delivers consistent power and precise control.

Heavy-Duty Load Capacity: Engineered to handle significant weights with ease, making it ideal for steel fabrication, machinery handling, and other intensive industries.

Optimized Trolley & End Truck Design: High-quality drive systems ensure smooth travel of both the hoist trolley across the bridge and the entire crane along the runway, with minimal vibration or jerkiness.

Application Scenarios

LH Electric Hoist Double Girder Cranes are the workhorses of numerous industries:

Manufacturing & Fabrication: Handling raw materials (steel coils, plates), moving heavy machinery, and positioning large components in assembly lines.

Warehousing & Logistics: Loading and unloading heavy goods, managing large pallets, and servicing bulk storage areas.

Steel Mills & Metal Processing: Transporting molten metal (with special safeguards), moving billets, and handling finished metal products.

Power Generation: Installing and maintaining turbines, generators, and transformers.

Paper & Pulp Mills: Handling large rolls of paper and maintenance of heavy equipment.

Automotive Industry: Moving vehicle chassis, engines, and large stamping dies.

Shipping & Portside Sheds: Handling heavy cargo within storage sheds.

LH electric hoist overhead crane is mainly used in machining workshop, metallurgical auxiliary workshops, warehouses, material, power etc to transfer, assembly, maintenance and handling operations.

Why the Double Girder Design is the Superior Choice for Heavy-Duty Lifting

Unlike single girder cranes, the double girder configuration provides a fundamental advantage in structural integrity. The two parallel girders create a rigid bridge that minimizes deflection—the bending or sagging under load. This results in:

Higher Hook Lift: Provides greater vertical clearance under the same runway conditions, maximizing usable workspace.

Exceptional Stability & Precision: Ensures smooth, accurate load positioning even at maximum capacity, crucial for precision tasks.

Greater Span Capability: Ideally suited for wider workshops and bays, offering reliable performance across long distances.

Extended Service Life: The robust design distributes stress more effectively, reducing wear and tear on components.

Conclusion

The LH Electric Hoist Double Girder Overhead Crane is more than just lifting equipment; it is a productivity multiplier engineered for strength, precision, and enduring performance. By combining the robust double girder bridge with a reliable electric hoist, it delivers an optimal solution for heavy-load handling across a vast operational area. Whether you are upgrading existing infrastructure or designing a new facility, integrating an LH Double Girder Crane system is a strategic investment in operational efficiency, safety, and long-term reliability.

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

https://ncranes.com

Tel

+86-17525962783