This Electric Single Girder Overhead Crane isn't just a piece of metal; it's the beating heart of efficiency in workshops, warehouses, assembly lines, and light industrial facilities worldwide. But what makes it the go-to choice for engineers and facility managers? Let's dive into the data, the design, and the undeniable advantages that make it indispensable.

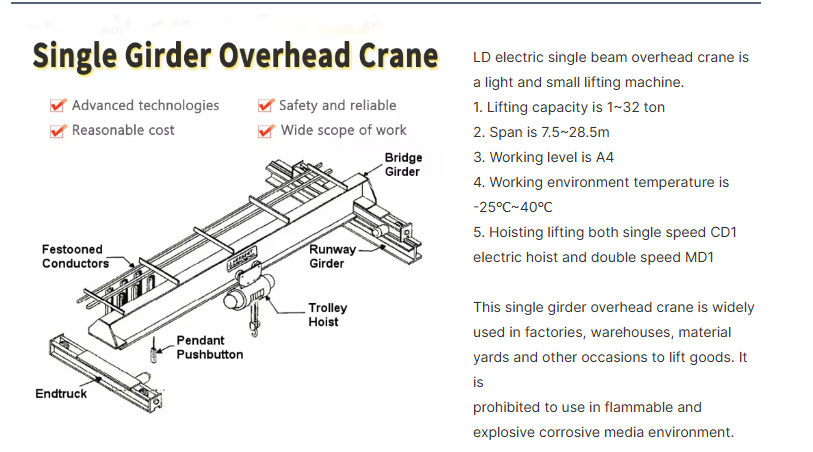

Anatomy of Efficiency: Breaking Down the Design

At its core, an Electric Single Girder Overhead Crane consists of a single bridge beam (the girder) supported by two end trucks that run on elevated runway rails. The electric hoist and trolley travel along the bottom flange of this girder. This simple yet brilliant configuration is the secret to its success.

Key Components & Their Impact:

Single Girder: Made from rolled steel sections or optimized welded boxes, it provides a robust yet lightweight structure. The single-girder design reduces deadweight by up to 30% compared to a double-girder system for equivalent capacities, leading to lighter supporting structures and lower initial building costs.

End Trucks & Runway: Equipped with precision wheels and motors, they facilitate smooth long-travel movement. Modern cranes feature frequency-controlled drives (AC/DC), which reduce start-up jerk and enable pinpoint positioning accuracy to within ±10 mm.

Electric Hoist: The powerhouse. Today's models predominantly use versatile wire rope hoists (e.g., capacities from 1 to 20 tons) or compact chain hoists for lighter duties. Motor technology has evolved to high-efficiency IE3 or IE4 class motors, slashing energy consumption.

The Numbers Don't Lie: Performance Data That Impresses

Let's talk hard facts. The capabilities of a standard Electric Single Girder Overhead Crane are not theoretical; they are proven on the factory floor every second.

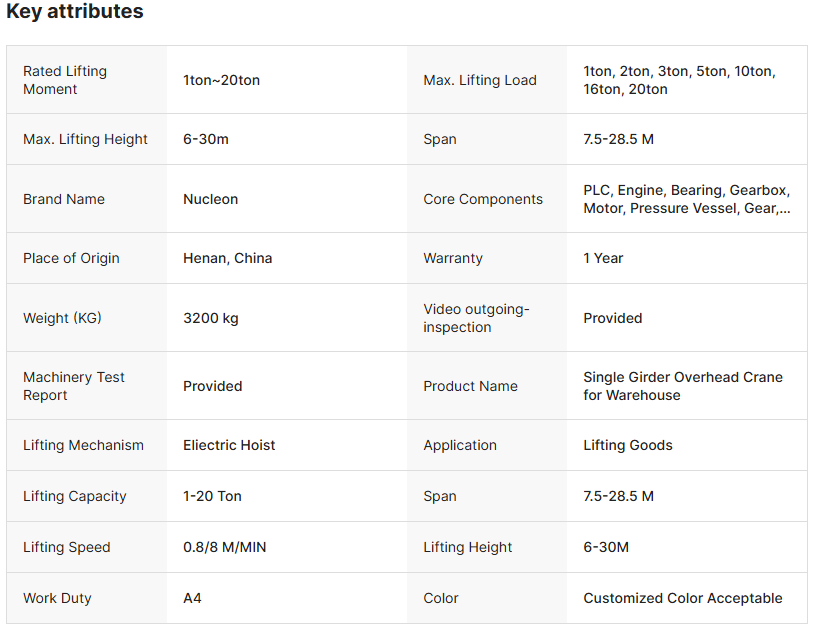

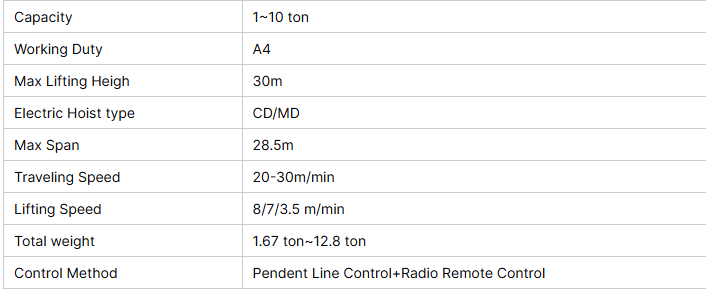

Lifting Capacity: Perfectly suited for light to medium-duty applications, standard models typically range from 1 ton to 20 tons. Special designs can push this further, but this range covers the vast majority of industrial needs.

Span Length: Efficiently serves building widths (span) from 5 meters to over 30 meters. For longer spans, the girder can be reinforced or supported to maintain rigidity.

Speed & Productivity: With three distinct motion controls—hoisting (up to 20 m/min), cross-travel (up to 30 m/min), and long-travel (up to 60 m/min)—these cranes drastically reduce load cycle times. In a typical parts-handling operation, this can translate to a 15-25% increase in material handling throughput.

Duty Cycle & Reliability: Built for consistent performance, they often conform to FEM/ISO Class 1M to 3M duty cycles. This means they are engineered for several starts per hour and reliable operation over years, with Mean Time Between Failures (MTBF) figures often exceeding 10,000 operational hours for key components.

Energy Savings: A modern 5-ton crane with an IE3 motor and variable frequency drive (VFD) can consume up to 40% less electricity than an older, direct-on-line starter model. For a two-shift operation, this can mean annual savings of thousands of dollars.

Why Choose Electric Single Girder? The Competitive Edge

Compared to mobile cranes or manual lifting, the advantages are crystal clear:

Space Maximization: It operates overhead, leaving every square inch of valuable floor space free for production, storage, and movement. This is a game-changer for high-density storage facilities.

Unmatched Precision & Safety: With push-button pendant or radio remote control, the operator can position loads with millimeter precision from a safe distance. This reduces product damage and, most importantly, lowers workplace accident risks by centralizing heavy lifting operations.

Cost-Effectiveness: Lower initial investment compared to double-girder cranes, reduced installation time, minimal maintenance (primarily lubrication and inspection), and the energy savings mentioned earlier lead to a remarkably low Total Cost of Ownership (TCO). The ROI is often achieved in under 24 months.

Adaptability & Intelligence: This is no "dumb" machine. Integration is key. Modern electric single girder cranes can be equipped with:

Anti-Sway Technology: Uses algorithms to automatically dampen load swing, increasing precision and safety.

Load Monitoring Systems: Provide real-time weight data and prevent overloads.

Smart Connectivity: Data on cycles, motor health, and usage patterns can be fed into a facility's IoT platform for predictive maintenance, preventing costly unplanned downtime.

The Verdict: More Than Just a Crane, It's a Strategic Asset

The Electric Single Girder Overhead Crane is the embodiment of intelligent industrial design. It takes a fundamental task—lifting—and transforms it into a seamless, efficient, and data-rich process. The numbers speak for themselves: higher throughput, lower costs, enhanced safety, and smarter operations.

For any business looking to optimize its material handling, boost productivity, and future-proof its operations, investing in a well-specified Electric Single Girder Overhead Crane isn't just a purchase; it's a strategic upgrade to the very backbone of the facility.

Ready to elevate your operational efficiency? Contact a trusted crane manufacturer today to discuss how a customized Electric Single Girder solution can streamline your workflow and strengthen your bottom line.

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable overhead crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable electric overhead crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

Tel

+86-17525962783