What is a fully automatic bulk material grab crane?

The fully automatic grab crane for bulk materials consists of a bridge frame, trolley and gantry travel mechanisms, a grab bucket, a remote monitoring system, and an electrical control system. It offers four control modes: full automation, semi-automation, remote manual control, and on-site manual operation. Designed with a double-girder and dual-rail structure, the crane is robust, durable, and capable of handling heavy loads. It is suitable for grabbing and transporting various bulk materials, including ores, slag, coke, coal, and sand.

Introduction

With the continuous advancement and development of intelligent crane technology, Newcleon Company remains committed to innovation, driving forward the trends of green technology, digitalization, and intelligent manufacturing. On the path toward embracing new technologies, the company continues to gather momentum for high-quality growth.

Recently, a globally renowned mining company based in Fujian placed an order for a batch of fully automatic grab cranes for bulk materials. As a Fortune 500 multinational mining corporation, the client specializes in the exploration, development, and technological application research of metal mineral resources such as copper, gold, zinc, lithium, silver, and molybdenum. The company is dedicated to the green and efficient development of mineral resources.

Key Features

Dual Hoisting Mechanism

The trolley is equipped with two sets of hoisting mechanisms, each featuring dual drum assemblies arranged symmetrically. This design ensures operational convenience, stability, high efficiency, and superior load-bearing capacity.Intelligent Warehouse Management System

The automated crane is integrated with a specialized warehouse management system that facilitates warehouse zone management, operational management, equipment management, scheduling, and report generation. By interfacing with the client’s production management system, the crane achieves a high level of intelligent operation.3D Warehouse Scanning System

A 3D scanning system performs real-time scanning of the entire warehouse area, generating 3D point cloud data. This data is transmitted via direct Ethernet connection to a point cloud processor and further relayed through wireless networks and optical fibers to the warehouse management system. This enables precise guidance for the crane’s loading tasks.5G Communication Technology

5G technology is integrated into the video monitoring system and the unmanned crane control system. Through 5G transmission, real-time 3D reconstruction and AI-based recognition and analysis are performed in the cloud. The results are then sent back to the site, guiding on-site production operations.

Application Scenario

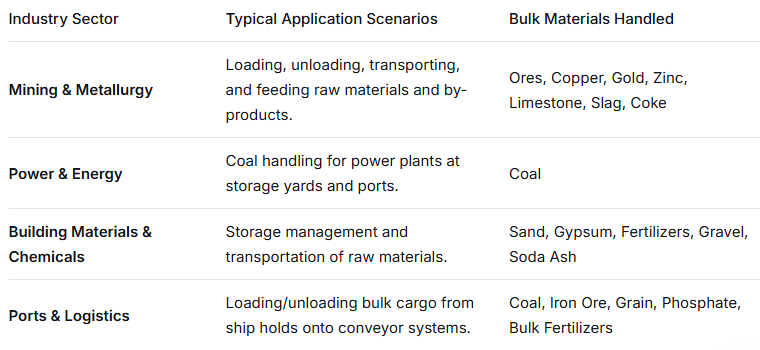

Newcleon's Fully Automatic Grab Crane is engineered for high-efficiency handling of bulk solids across a wide range of industrial sectors. Its robust design and advanced intelligent features make it an ideal solution for automating material handling processes.

The table below outlines the primary industries and their specific applications:

As a pioneer in intelligent manufacturing, Newcleon’s fully automatic grab crane for bulk materials represents a breakthrough in automated and intelligent material handling. With its advanced features such as dual hoisting mechanisms, intelligent warehouse management, 3D scanning, and 5G integration, the crane sets a new standard for efficiency and innovation in the mining and bulk material handling industries.

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable overhead crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable electric overhead crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

Tel

+86-17525962783