一、Understanding the Basic Structural Design

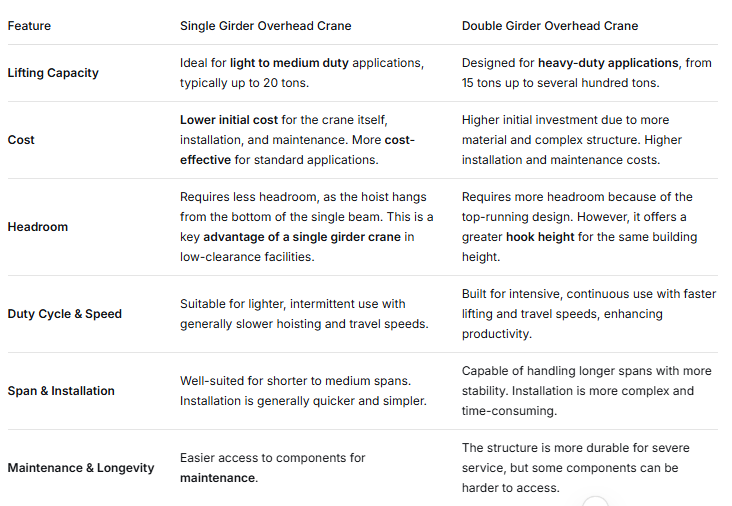

Choosing the right equipment is crucial for the efficiency and safety of your material handling operations. One of the most fundamental decisions you'll face is selecting between a single girder overhead crane and a double girder overhead crane. While they may look similar, their structural design, capabilities, and ideal applications differ significantly.To make the right choice, you need to understand the practical implications of their structural differences. The table below outlines the critical factors in the single girder vs double girder debate.

A single girder overhead crane features one main beam (the girder) that spans the bay, with a hoist and trolley that move along the bottom flange of this beam. This design is simpler and more compact.

A double girder overhead crane is constructed with two main beams that run parallel to each other, connected by end trucks. The hoist and trolley move on a rail installed on top of the two girders, creating a more robust and capable structure.

二、Advantages and Disadvantages of Single Girder Cranes

Cost-Effective Solution: Lower initial price and total cost of ownership.

Ideal for Low Headroom: Maximizes lifting height in buildings with height restrictions.

Lighter Weight: Puts less stress on the building structure.

Simpler Installation and Maintenance.

Lower Lifting Capacity limits its use for heavier loads.

Generally slower operating speeds.

Less suitable for intensive, 24/7 duty cycles.

三、Advantages and Disadvantages of Double Girder Cranes

Higher Lifting Capacity for demanding industrial tasks.

Higher Hook Height, providing better use of the building's cube.

Greater durability and longer service life under severe conditions.

Faster lifting and travel speeds for increased productivity.

Can be equipped with more advanced features like walkways and magnet systems.

Higher Initial Cost and total investment.

Requires more headroom for operation.

Heavier weight may require a more robust (and expensive) building structure.

四、Application Scenarios: Which Crane is Right for You?

Opt for a single girder overhead crane in these situations:

Workshops and Warehouses: Handling light to medium duty loads like machinery parts, packaged goods, or raw materials.

Maintenance Bays and Repair Shops: Where lifting needs are infrequent or for periodic equipment servicing.

Applications with Strict Budgets: Where cost-effectiveness is a primary driver.

Facilities with Low Headroom: Where maximizing clear space under the crane hook is critical.

When to Choose a Double Girder Overhead Crane

Opt for a double girder overhead crane in these situations:

Heavy Manufacturing and Steel Mills: For continuous handling of heavy raw materials, coils, or large fabricated pieces.

Power Plants and Shipyards: Where lifting capacities exceed 20 tons and reliability is paramount for heavy-duty applications.

Pulp and Paper Mills, and Foundries: Demanding environments that require high-duty cycles, speed, and durability.

Applications Requiring High Hook Height or Long Spans: Such as in large assembly halls or storage facilities.

五、Conclusion: Making the Informed Choice

There is no universal "best" option—only the best crane for your specific requirements. A single girder overhead crane offers an efficient and cost-effective solution for lighter, less frequent lifting tasks. In contrast, a double girder overhead crane is the indispensable workhorse for heavy-duty applications, intensive use, and heavier capacity needs.By carefully evaluating your required lifting capacity, budget, facility headroom, and duty cycle, you can confidently answer the question: "Which is better, a single or double girder crane for my facility?"

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable overhead crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable electric overhead crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

Tel

+86-17525962783