What is a Jib Crane? A Comprehensive Guide

A jib crane is a highly versatile and efficient piece of material handling equipment. At its core, it consists of a horizontal boom (or jib) that is mounted to a vertical support structure. This boom can rotate, providing a circular work area for lifting and moving loads. Jib cranes are ideal for repetitive tasks in a specific area, offering a cost-effective solution to improve workflow and reduce manual labor.This guide will delve into three main types of jib cranes: the Wall Mounted Jib Crane, the Column Mounted Jib Crane, and the Wall Travelling Jib Crane. We will explore their unique features, advantages, and typical applications.

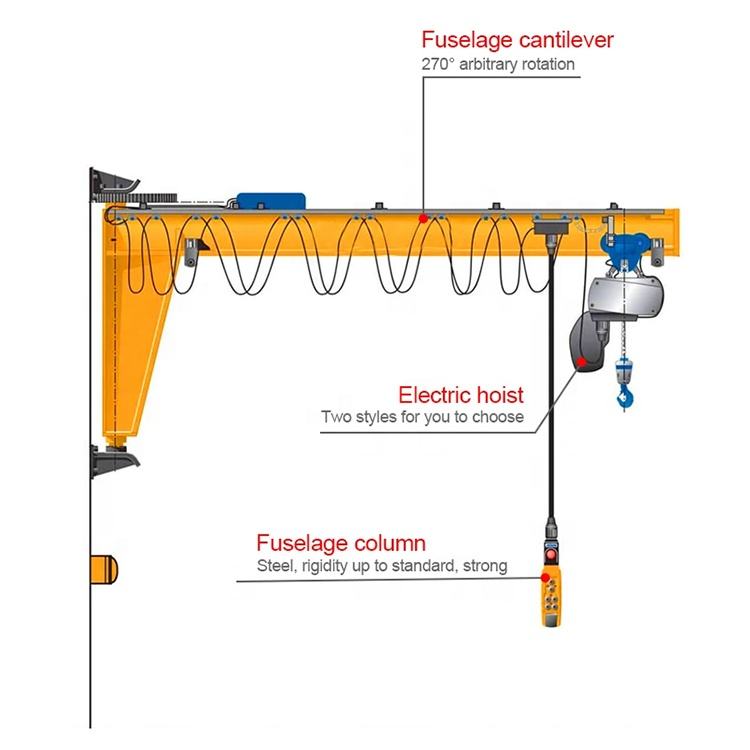

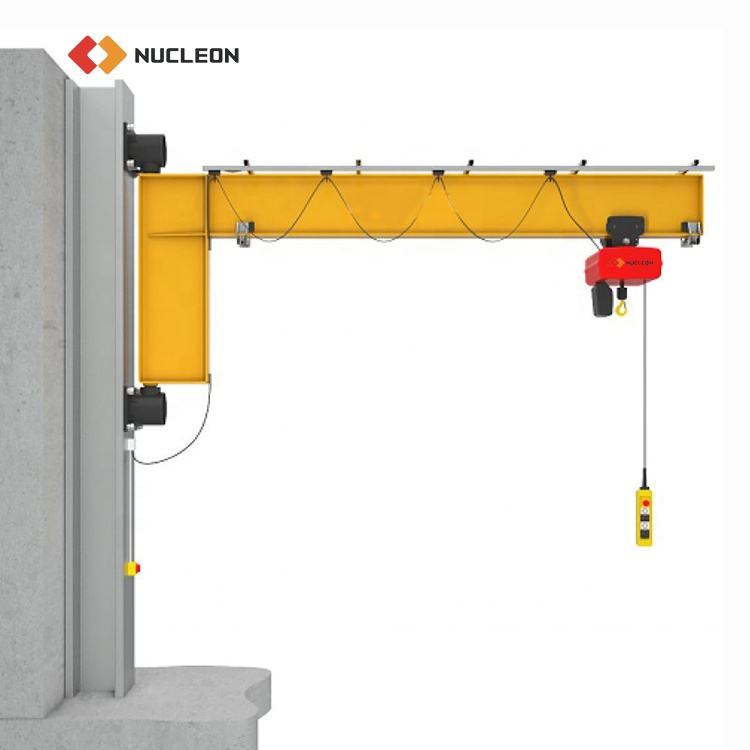

1. Wall Mounted Jib Crane

Product Introduction

A Wall Mounted Jib Crane is a space-saving solution designed to be directly attached to an existing building column or a sturdy structural wall. It does not require a dedicated floor-mounted foundation, making it an excellent choice for facilities where floor space is at a premium. The wall mounted jib crane provides reliable lifting capacity along a wall or in a corner.

Key Features & Advantages

Maximizes Floor Space: By mounting on the wall, it keeps the floor completely clear, allowing for unobstructed movement of personnel and equipment.

Cost-Effective Installation: Eliminates the need for costly and disruptive concrete foundations.

Structural Support: Relies on the building's structural integrity, which must be verified prior to installation.

Ideal for Repetitive Tasks: Perfect for loading/unloading machines, assembly stations, or conveyor lines along a wall

Application Scenarios

Workshops: For servicing machinery placed against walls.

Assembly Lines: Lifting components to workstations.

Loading Bays: Moving goods from trucks to a fixed point inside.

CNC Machine Feeding: Efficiently loading and unloading materials on CNC machines positioned near walls.

2. Column Mounted Jib Crane

Product Introduction

A Column Mounted Jib Crane, also known as a free-standing jib crane, is supported by a single, robust mast anchored to a concrete foundation on the floor. This design makes it completely independent of the building's structure. The column mounted jib crane offers 360-degree rotation and can be installed virtually anywhere on the shop floor.

Key Features & Advantages

Full 360-Degree Rotation: Provides complete coverage in a circular area around the mast.

Independent Structure: Does not place any load on the building, offering maximum flexibility in placement.

High Capacity: Typically capable of handling heavier loads compared to wall-mounted models.

Flexible Placement: Can be installed in the center of a room, next to equipment, or anywhere a foundation can be poured.

Application Scenarios

Standalone Workstations: Creating dedicated lifting points in the middle of a production area.

Service Bays: For maintaining vehicles or large equipment.

Foundries and Fabrication Shops: Handling heavy molds, steel plates, or fabricated parts.

Staging Areas: Where materials need to be lifted and rotated in multiple directions.

3. Wall Travelling Jib Crane

Product Introduction

A Wall Travelling Jib Crane combines the features of a standard wall mounted jib crane with an added dimension of mobility. The entire crane system, including the mast and boom, is mounted on a runway track that is fixed to the wall or supporting structure. This allows the wall travelling jib crane to move laterally along the length of the track, dramatically increasing its coverage area.

Key Features & Advantages

Extended Coverage: The ability to travel along a wall provides a large, rectangular work envelope instead of a fixed circle.

High Versatility: Can service multiple workstations, machines, or bays along a single wall.

Efficient Material Flow: Ideal for moving loads from one end of a production line to another without requiring multiple cranes.

Space Optimization: Still maintains the floor-space-saving benefit of a wall-mounted design.

Application Scenarios

Long Production Lines: Serving a series of assembly stations along a wall.

Warehousing: For loading and unloading goods along a long storage wall.

Shipping and Receiving: Covering the entire length of a loading dock.

Large Machinery Halls: Providing maintenance access to different sections of a large machine.

Why Choose Our Jib Cranes? Key Benefits Across All Types?

No matter which type of jib crane you choose, our products are engineered for performance and reliability. The core advantages of integrating a jib crane into your operation include:

Increased Productivity: Speed up material handling processes and reduce worker fatigue.

Enhanced Safety: Minimize the risk of injuries associated with manual lifting.

Improved Ergonomics: Allow operators to position loads with precision and ease.

Cost Reduction: Offer a more affordable alternative to large overhead bridge cranes for localized tasks.

Customizable Solutions: We offer various boom lengths, capacities, and rotation options to meet your specific needs.

HI! Parter

Regarding your actual requirements, are you still unsure about which suitable overhead crane to choose? Please contact our professional team immediately forfree consultation and personalized quotations. We will provide you with professional services and select the most suitable electric overhead crane for you to optimize your operations, ensuring safety, efficiency and high productivity.

GET IN TOUCH

sale@nucleoncranes.global

Tel

+86-17525962783